References

Treatment of Drinking Water

Dosing Systems for rapid decarbonisation

Project location:

Rhineland-Palatinate, Germany

Date:

2023/2024

Systems used:

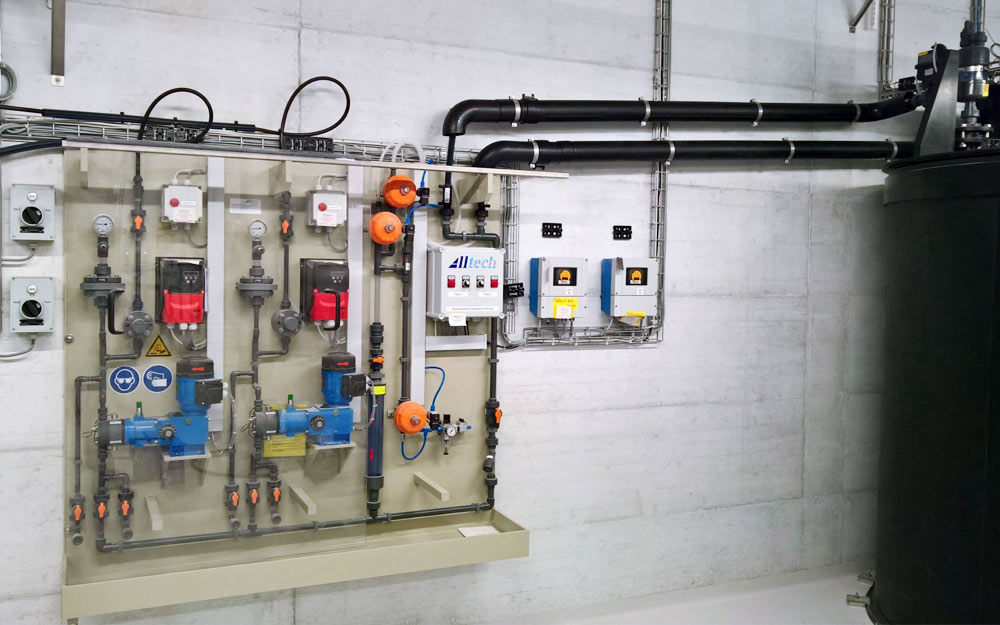

Storage tank with 25 m³ usable volume for 50% caustic soda solution, dilution station for diluting caustic soda solution with 2 dosing pumps on one dosing line, storage tank with 15 m³ usable volume for 25% (diluted) caustic soda solution, dosing station with 4 dosing pumps on 2 dosing lines.

Description:

Before the rapid decarbonisation system was installed, the drinking water in the waterworks’ supply area had a hardness level of 20.2 °dH (German hardness), which is considered “hard water”. The use of hard water leads to increased consumption of cleaning agents and detergents in private households, which not only results in higher costs, but also has a negative impact on the environment due to increased chemical pollution of waste water. In addition, limescale deposits cause damage to household appliances and municipal supply systems, which leads to higher maintenance costs.

The commissioning of the SEC system has reduced the hardness of the drinking water to 12 °dH. As a result, consumers are now supplied with ‘soft’ water, which both reduces the use of detergents and cleaning agents and minimises the environmental impact.

Storage tanks for chemiclas with all relevant safety features

Two chemical storage tanks, each with a usable volume of 25 cubic metres, were installed inside the waterworks building to store 50% caustic soda. These tanks meet the requirements of the German Water Resources Act (WHG) and have the necessary type approval for the safe storage of substances hazardous to water.

All safety requirements, in particular DIN EN ISO 14122, are complied with in order to protect the operating personnel from accidents at work. The chemical storage tanks are filled from the outside via the TABESY tank filling system, which is installed in a separate filling nozzle cabinet.

Dilution of the caustic soda solution for drinking water treatment

As part of the decarbonisation process, the 50% caustic soda solution is diluted to 25% to enable precise adjustment of the pH value in the drinking water. 2,400 litres per hour of 50% caustic soda are taken from the storage tanks and then diluted to 4,800 litres per hour of 25% caustic soda. This diluted caustic solution is stored in a 15 m³ tank that fulfils all legal requirements regarding leakage protection and environmental protection.

Dosing station with spilling and leakage protection for personnel and the environment

Dosing into the decarbonisation process takes place from the storage tank for the diluted caustic soda solution via two dosing lines. The dosing station is housed in chemical-resistant protective cabinets with integrated leakage trays. These protective devices ensure the safety of the operating personnel and the environment by protecting against possible leaks and preventing splash accidents.

Soda dosing for pH-correction of water

Project location:

Ipsach, Switzerland

Date:

2022

Systems used:

POLYMAT soda powder solution system (bagged goods), bag feeding system and screw conveyor, dosing station with FKM piston-diaphragm dosing pumps and iReg intelligent control.

Description:

As part of the renewal of the Ipsach seawater treatment plant, which will provide drinking water for 70,000 people, Alltech delivered a soda treatment system with a dosing station for soda solution. The water from Lake Biel goes through several treatment stages before it can be provided to end-users. One stage of treatment is reverse osmosis. The surface water treated in this way is mixed with ultrafiltered water, and the pH of the mixed water is raised before it is ozonized to kill viruses and bacteria. After this process stage, the water is treated with activated carbon to eliminate micro-pollutants. Finally, the water is disinfected with UV light before being fed into the drinking water network.

pH-correction of reverse osmosis-treated water with soda

A portion of the treated water from Lake Biel is treated using reverse osmosis, which fully softens it. Due to the lack of hardness-forming minerals, the pH of the water shifts significantly below 7. The reverse osmosis-treated water is mixed with ultrafiltration permeate, and the pH of the water is slightly raised through soda dosing. The mixed water has low hardness, so end-customers can save on laundry detergents, regenerating salts, and decalcifying agents.

The soda powder is conveyed into the treatment plant using a conveyor screw. The POLYMAT plant used is a fully automatic 3-chamber flow-through system. It produces a soda solution of consistent concentration from the powder delivered in bags.

The control system of the POLYMAT dissolution plant communicates via Profinet with the water plant’s control system and transmits all important parameters and operating states.

Dosing station with piston-diaphragm dosing pumps and intelligent iReg control

The soda solution is dosed into the pH-correction process using a dosing station with two FKM piston-diaphragm dosing pumps in operation and one dosing pump in reserve, equipped with the latest intelligent iReg control. The dosing pumps communicate with the process control system of the water plant and transmit all important pump data and flow rates.

Disinfecting surface water with calcium hypochlorite

Project location:

Middle East

Date:

2018

Systems used:

SOLVIMAT solution preparation and dosing system for powdery and granular products, dosing stations with piston-diaphragm-dosing pumps FKM, floor mounted on skids for pre- and postchlorination.

Description:

In order to obtain drinking water in superior quality, surface water in the water treatment plant Sardasht is treated with calcium hypochlorite.

Microbially contaminated surface water has to be treated in a multi-stage procedure

In order to obtain drinking water from microbially contaminated surface water from rivers or lakes, the surface water has to be treated in a multi-stage process. First, the particles are removed by flocculation and filtration, after this the disinfection of the contaminated raw water takes place.

In Sardasht, the raw water is disinfected by the use of calcium hypochlorite. Delivered in bags, the calcium hypochlorite is prepared by the semi-automatic solution preparation and dosing system SOLVIMAT.

A great advantage of the SOLVIMAT is, that it reliably prepares suspensions or solutions from bulk products with various granulations, from fine powder to boulder/granular and in variable product qualities. The solution is loaded in batch operation and hereby enables the adherence to the required maturity times. In addition, the two chamber principle allows continuous solution discharge.

In Sardasht up to 3000 l/h of calcium hypochlorite solution are prepared.

The feeder was specially developed for this project. The bags with calcium hypochlorite are placed in hinged feeders, opened and emptied dust-free. This type of discharge, combined with suction and powder retention, minimizes the health hazards of operating personnel.

The uncomplicated communication with the system is carried out by means of a touch-panel mounted on the front of the switch cabinet. This enables the setting of all operating parameters and displays all relevant system conditions in graphic form.

The inflowing solution water quantity is permanently monitored and stored by a flow meter with counter and impulse encoder, so that in the event of a power failure, the system can be restarted without intervention by operating personnel.

Furthermore, the maintenance requirement of SOLVIMAT is minimal.

Dosing stations for pre- and postchlorination

During pre-chlorination, the basic load is disinfected based on experience. In the post-chlorination, the residual chlorine content is measured in already treated water and the amount still to be dosed is determined, so that the residual chlorine content then achieved ensures that the drinking water remains germ-free up to the water point.

During pre- as well as during post chlorination the proven and robust piston diaphragm dosing pumps FKM, floor mounted on skids, are used. Two dosing pumps per skid (one in duty, one stand-by) guarantee for continuous dosing of the solution for disinfection.

The use of SOLVIMAT preparation and dosing systems can help to supply high-quality drinking water in regions with low water ressources.

Chemical storage and dosing system for the treatment of drinking water

Project location:

Baselland (Switzerland)

Date:

2016

Systems used:

Storage and dosing system for hydrogen peroxide consisting of tank filling unit TABESY including local control panel, PE storage tank with collecting bund and monitoring devices, dosing station with piston-diaphragm dosing pumps

Description:

For a new drinking water treatment plant in Switzerland, Alltech has planned, produced, installed and commissioned a storage and dosing system for hydrogen peroxide.

Contaminated groundwater required the construction of the drinking water treatment plant

The construction of the drinking water treatment plant with a cleaning capacity of 20,000 cubic meters per day was required by the pollution of the groundwater with micro-impurities (including chlorine substances, herbicides and pharmacologically active substances). The plant uses a three-stage process for drinking water treatment: in the first step, the groundwater is treated with ozone and hydrogen using the Advanced Oxidation Process (AOP) process. After this oxidation process, the adsorption stage follows, in which the water is further purified with activated carbon. Finally the purified drinking water is fed into the public drinking water supply in a very high quality after passing a membrane filter process where the activated carbon is removed.

Alltech storage and dosing systems for peroxide are used in the advanced oxidation process

The advanced oxidation process is a process for the chemical treatment of organic and inorganic substances in water. In this project, Alltech is using the tank filling unit TABESY to fill the two storage tanks with peroxide. This includes the local control and monitoring system with alarm function for overfill and leakage. The cylindrical flat bottom tanks made of PE are designed according to WHG and have the type approval No. Z.40.21-27 of the DIBt (German Institute for Construction Technology). For Switzerland, the tanks have the certificate of product testing according to KVT of the SVTI (Swiss Association for Technical Inspections). Thanks to the included collecting bund, the operating personnel and the environment are perfectly protected. The dosing station is equipped with robust piston-diaphragm metering pumps type FKM. The dosing capacity can be adjusted linearly and continuously in the range of 0 to 100%. The dosing accuracy is better than + – 1%.

Soda ash solution preparation system for the water supply works Lengg (Zurich)

Project location:

Lengg (Zurich)/Switzerland

Date:

2016

Systems used: :

POLYMAT solution and dosing systems for soda ash

Description: :

Alltech provides Soda Ash solution preparation system as part of the modernisation of the neutralisation plant of the water supply works SWW Lengg (Zurich). The lake water supply works Lengg is located on the right side of Lake Zurich. It has a maximum daily capacity of 250,000 m3 of drinking water and is a major water supply works for Zurich.

The water treatment is highly efficient and environmental friendly. Even under unfavorable conditions safe drinking water has to be produced. The fulfillment of these demands is much more complex for lake water compared to groundwater or spring water, because surface water can contain impurities and is exposed to the dangers of possible contaminations.

From lake water to drinking water

The raw water flows through natural sand filters and activated carbon filters to remove contained particles and to reduce the particles biologically. Between the different filtration steps, the water is treated with ozone. The ozone itself is degraded completely in the activated carbon filters. (Source: City of Zurich)

Protect the concrete water storage basins at low pH values

The treated drinking water is stored in concrete basins before it is fed into the drinking water network of the city of Zurich. During certain seasons lower pH values of the water would damage the concrete structure of the water storage basins. To prevent this, the neutralisation system of the lake water supply works SWW Lengg in Zurich was modernized and a new soda ash solution preparation system was taken into operation.

POLYMAT solution and dosing systems for soda ash

In order to increase the pH-value of the stored drinking water, soda ash is used. Two POLYMAT solution preparation and dosing systems will be used in the water works Lengg to prepare and dose a soda solution into the drinking water storage basins. The fully automatic POLYMAT system provides the optimum solution quality. Particularly noteworthy is the electrical control system with a robust, high-resolution color touch panel operation. The output of each system used in this project is 4,000 l / h of prepared solution. The POLYMAT is a three-chamber flow-through system. The dry material feeder is made of stainless steel and can be used for both powders and granular products. The hopper for the soda powder has a capacity of about 150 liters. To guarantee a high dosing accuracy the hopper has an air loosening device and a pneumatic knocker. Other proven components are the high performance disperser and the robust and durable agitators which guarantee a homogeneous solution in the preparation and maturity chamber and also prevent sedimentations. The dilution water supply unit consisting of check valve, strainer, reducing valve and manometer made of stainless steel with oil dampening and solenoid valve ensures a continuous water supply into the mixing system. The amount of water is measured via an electromagnetic flowmeter and controls proportionally the soda-addition to keep the solution concentration constant.

Commissioning and pilot phase successfully completed

Since the commissioning in early summer 2016 has been successfully completed, and the pilot phase has confirmed the functionality, the extension with a further POLYMAT preparation and dosing system in the 2nd half of 2016 is planned.

CHLORINE DIOXIDE SYSTEM FOR TREATING WATER FROM LAKE CONSTANCE.

Project location:

Kreuzlingen/Schweiz

Date:

2013/14

Systems used: :

OXICOM chlorine dioxide system, tank filling system TABESY, dosing and dilution station for hydrogen chloride (HCl) and storage tanks for polyelectrolytes (à 50m³)

Description: :

The Kreuzlingen lake water works supplies the residents and companies of the Swiss town of Kreuzlingen with a supply grid of approx. 105 km. Recently a new plant began operation with which the treatment of approx. 10,000 m³/d of water from Lake Constance for drinking water is ensured.

TREATMENT IN SEVERAL PHASES.

At the lake water works in Kreuzlingen the water is purified to drinking water through treatment with several phases with flocculation, sand filter, and ozoning and carbon filtration. As protection a minimal amount of chlorine dioxide is used. Here the chlorine dioxide system OXICOM from Alltech is used. For the protection of the supply network and the safe disinfection of the drinking water, chlorine dioxide is perfectly suited. The advantages in contrast to disinfection with chlorine are amongst others a high oxidation level and a high odour and taste threshold. With OXICOM the user takes advantage of these benefits as OXICOM produces chlorine dioxide through the hydrochloric acid – chlorite process. Disinfection with chlorine dioxide has fewer risks for operating personnel as both base chemicals (hydrochloric acid and sodium chloride) are stored separately prior to the creation of chlorine dioxide.

COMPLETE SERVICE PACKAGE FOR USER-FRIENDLY SYSTEMS.

OXICOM enables the direct and proportional production and dosing of the chlorine dioxide amount required. Only as much chlorine dioxide is produced as required to prepare the water. The maximum output from OXICOM chlorine dioxides systems that are supplied fully pre-assembled and tested, is 12,000 g ClO2/h. Also installation and initial operation is undertaken by Alltech.

DOSING SYSTEMS FOR THE TREATMENT OF NILE WATER.

Project location:

Maadi/Egypt

Date:

2008

Systems used: :

FKMF metering pumps

Description: :

Maadi is the green suburb in Cairo and is one of the more popular places to live. Maadi extends along the Nile and was in past times, at the time of the long caravans of Arabia on the West bank of the Nile at Giza, an important hub. Today, the location of Maadi on the Nile plays a decisive role for the drinking water supply for the almost two million inhabitants. The newest dosing systems from Alltech transform the waters of the Nile to drinking water.

PRETREATMENT OF WATER FROM THE NILE.

For this project, Alltech supplied in addition to the chlorine gas dosing system also the first six metering pumps from the new FKMF range with a dosing output of 2400 l/h (max.) each. The pumps with suction and pressure pulsation evaporator and pressure sustaining valve were already preassembled at the company works in Weingarten near Karlsruhe on a solid console. The operators of the water preparation plant could install the compact stations on-site with no problems. In the drinking water preparation plant in Maadi the metering pumps for the dosing of aluminium sulphate were used to pre-treat the raw water that is taken directly from the Nile (flocculation).

PREPARATION OF 400,000 M³ OF DRINKING WATER PER DAY.

The discharge of the prepared solution is from concrete batching tank and the aluminium sulphate is dosed directly in the inlet. The setting of the dosing quantity is undertaken directly through the frequency regulator directly built onto the motor in a rage of 2-100 Hz. For pre-chlorination two vacuum safety dosing systems from the VACUTROL range (one „operating“, one „stand-by“) each with an output of max. 120 kg Cl2/h. For subsequent chlorination there are six automatic VACUTROL (4 „operating“, two „stand-by“) each with an output of 25 kg Cl2/h. The thus required maximum operating output of 220 kg Cl2/h is provided through 2 compact safety evaporators (one „operating“, one „stand-by “). The high quality of the drinking water is created on the one hand through the automatic post-chlorination through the regulator unit DOSITROL, on the other through fine filtration. Through the ambient air monitoring and implemented safety technology a high level of reliability is given in the preparation of the drinking water. In Maadi, 400,000 m³ of drinking water per day is prepared using the Alltech dosing systems.

METERING PUMPS AND DOSING SYSTEMS FOR CHLORINE GAS DOSING.

Project location:

El Alamein/Egypt

Date:

2004/05

Systems used::

Metering pumps for drinking water treatment and a chlorine gas dosing system

Description: :

El Alamein, Egypt, is situated on the coast of the Mediterranean, some 110 km west of Alexandria. Raw water is guided to the Alamein treatment plant from the Nile through the Al Mahmodeya channel over a distance of 40 km. Here for drinking water treatment metering pumps and a chlorine gas dosing system from Alltech are used. For the flocculation process, 10 piston diaphragm metering pumps type FKM with an output of 1,280 l per hour each dose the aluminium sulphate solution for flocculation. The disinfection of the raw water is undertaken with manually adjustable VACUTROL vacuum safety dosing systems.

THE RESULT: TOP QUALITY DRINKING WATER.

The high quality of the drinking water is produced on the one hand through the automatic post-chlorination with the DOSITROL, regulating system and on the other through fine filtration. The total of six chlorine gas devices are supplied with the corresponding quantity of gas from two compact safety evaporators. Through the ambient air monitoring and applied safety technology, the highest level of reliability is provided to treat the water. This high-quality drinking water not only improves the hygienic conditions for the population, but is also a requirement to strengthen the tourist industry in the area. Equally, other industries are also strengthened. The treated water supplies the north coast from Alamein City to Matroh City, near the Libyan border. This means the supplying of approx. 2 million people with best quality drinking water. In order to meet this demand, the drinking water treatment plant at Alamein that extends over an area of 1,200 x 800 m produces 180,000 m³ of drinking water a day.